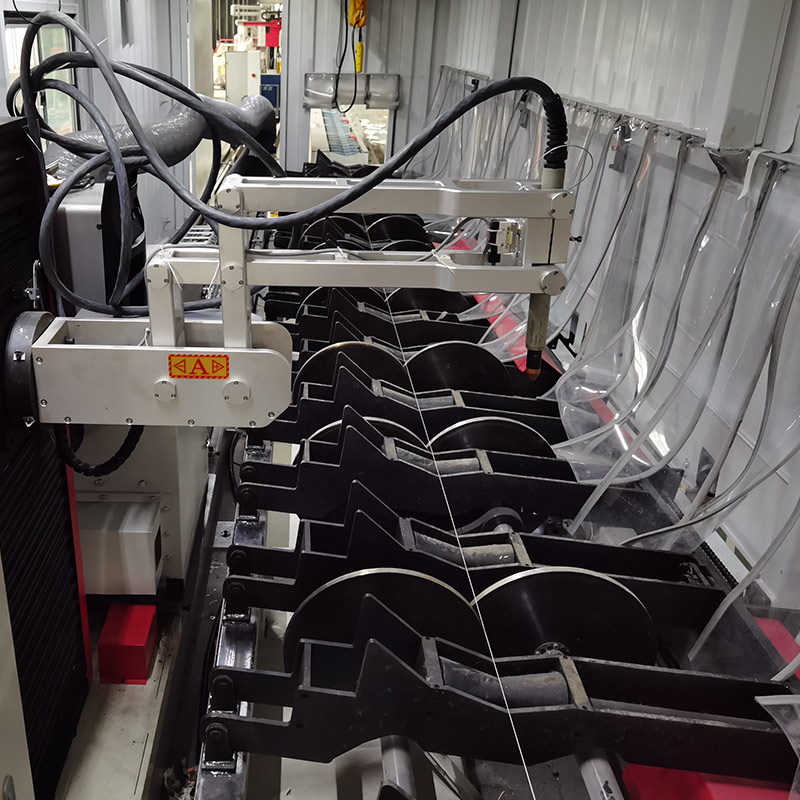

CNC Pipe Cutting Machine equipped with high-performance CNC cutting software; Flame/Plasma Cutting; 3-6 Control Axises; Imported Original IPC numerical control with touch screen & man-machine interface; Drive-by Panasonic Servo motor, High positioning, and moving precision; manual 3 jaws linkage self-centering chuck, 6 support trolleys; effective cutting length 12m; standard configuration of Hypertherm Powermax 105; chuck type driving system as standard (optional roller bench type).

Flame/plasma cutting; 3-6 control axes; With originally imported IPC from Taiwan to achieve numerical control via touch screen & man-machine interface; High positioning and moving precision; chuck+ roller bench-type driving system as standard; two rows of big wheels coated with stainless; built-in V shape roller conveying system.

Pipe Diameter Applicable: DN400/DN600/DN800/DN1000/DN1200/DN1500

Pipe Wall Thickness: 1-25mm (plasma cutting) or as per plasma generator;

5-60mm (flame cutting)

Cutting Speed: Plasma Cutting Speed: 50-3800mm/min

Flame Cutting Speed: 50-750mm/min

Number of Axis Under Control: 3-6 Axis

The angle of Bevel: Plasma Cutting: ±45° (adjustable)

Flame Cutting: ±60° (adjustable)

Cutting Pipe Length: ≤12000mm

Max Load Pipe Weight: 4000KGS

CNC System: Original import IPC

Control Way: Full CNC control with touch screen and man-machine interface

Integrated Precision of the Machine:

Portrait Moving Error: ≤±0.2mm/1000mm

Turning Angle Error: ≤1° per 180

Surface Quality: Clean and no dregs

Repeat Positioning Accuracy of Generatrix: ≤±0.3mm

Pipe cutting industry

After-Sale Service Guideline: ” Worry what users worry, think what users think ”

Within/beyond the warranty period, when the equipment gets out of order or is damaged, the company will provide technical consulting services without or with a charge. For customer advisory, the company will supply responses on the phone within 4 hours and written replies within 8 hours. If the customer requires, within 24 hours (within the distance of 800 KM) or within 48 hours (above 800 KM), the company will dispatch experienced engineering technical personnel to the customer site to analyze and guide maintenance. They will not leave until the fault is cleaned and the customer is satisfied.