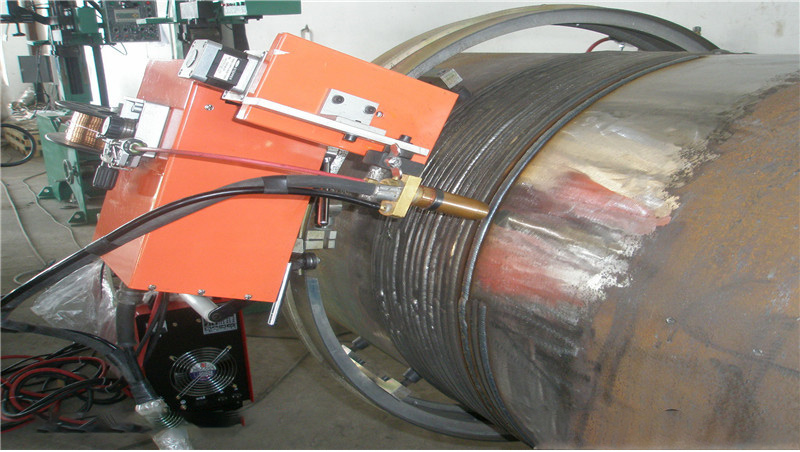

The orbital automatic pipe welding machine is used in the petrochemical, boiler, refrigeration, medical, voyage, pressure vessel, shipping, food machine, atomic power industries, etc.

The applicable scope is O.D. φ16mm~φ230mm and pipe-pipe, pipe-elbow, pipe-flange, pipe-valve body, etc., carbon steel, alloy steel, stainless steel, and so on materials butt welding of wire feeding or no wire feeding autolysis.

Diameter of Pipe: Φ16-40, Φ36-90, Φ70-160, Φ140-230

Wall Thickness of Pipe: 1-10mm

Applicable Materials: Carbon steel, Alloy steel, Stainless Steel, Cryogenic steel, etc.

Welding Speed: 0.4-3 RPM, 0.2-2 RPM, 0.1-1RPM, 0.07-0.5 RPM

Width of Oscillating: ± 8 mm

Speed of Oscillating: 0.5-10mm/s

Wire Feed Speed: 0-1500mm/min

Cooling Mode: Water-cool

Dip Angle of Weld Gun: 0-45°

Power Supply and Controlling System:

Rated Input Voltage: 380v

Rated Input Capacity: 11.5KVA

Rated Input Power: 9.0kw

The orbital automatic pipe welding machine is used in the petrochemical, boiler, refrigeration, medical, voyage, pressure vessel, shipping, food machine, atomic power industries, etc.

After-Sale Service Guideline: ” Worry what users worry, think what users think ”

Within/beyond the warranty period, when the equipment gets out of order or is damaged, the company will provide technical consulting services without or with a charge. For customer advisory, the company will supply responses on the phone within 4 hours and written replies within 8 hours. If the customer requires, within 24 hours (within the distance of 800 KM) or within 48 hours (above 800 KM), the company will dispatch experienced engineering technical personnel to the customer site to analyze and guide maintenance. They will not leave until the fault is cleaned and the customer is satisfied.