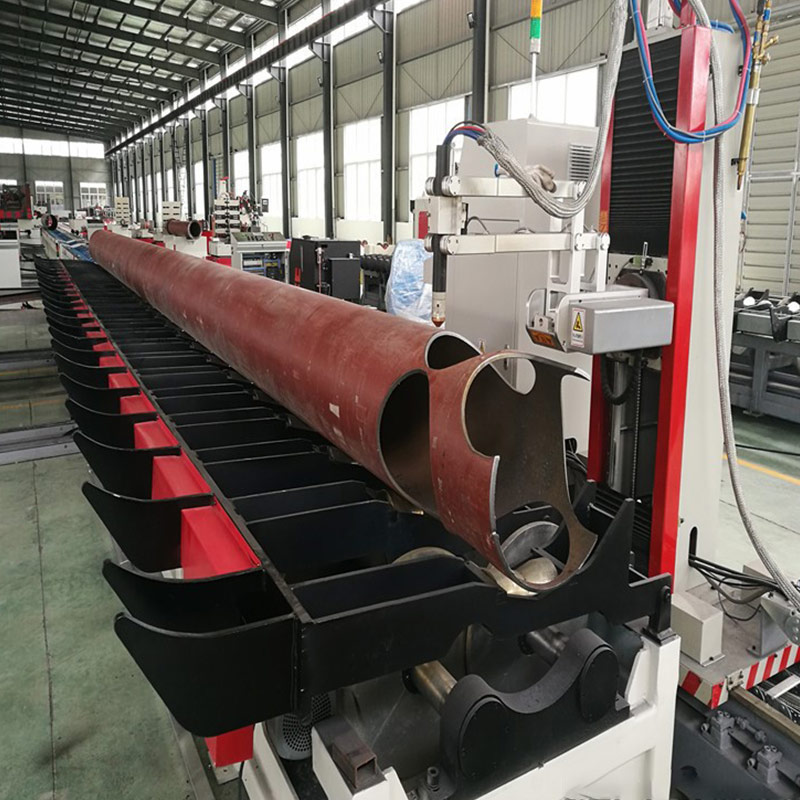

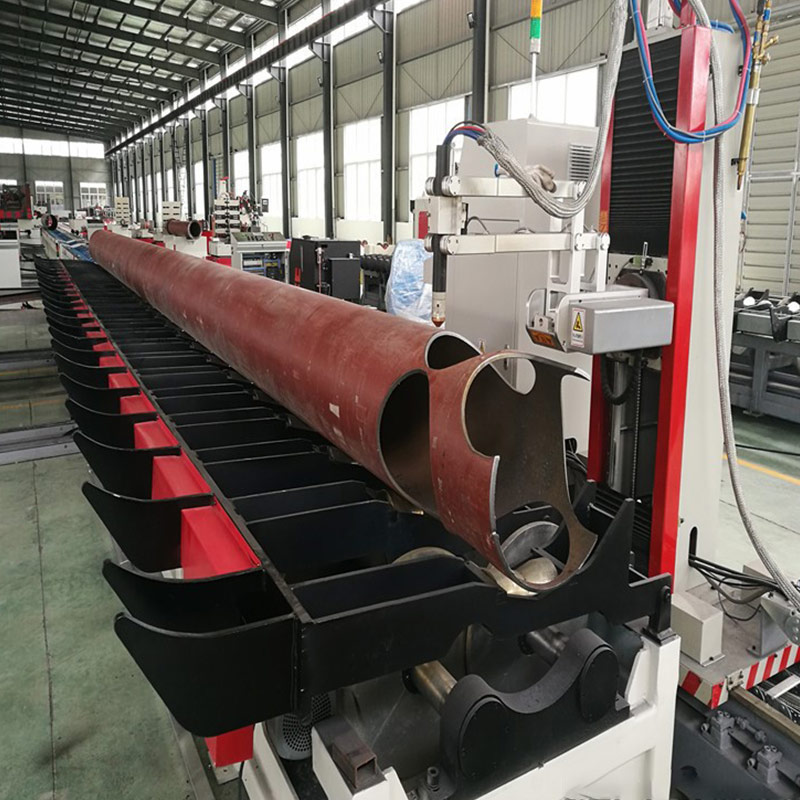

Flame/Plasma Cutting machine; built-in motor roller conveying system; the roller-bench type structure with three rows of small wheels coated with stainless steel or two rows of big wheels coated with stainless. Driving by Servo motor + Reducer; control with PLC cutting system; CNC cutting to length controlled by the man-machine interface.

The online performance of the pipe flame beveling and cutting machine is very good (designed as per the online equipment of the production line).

The pipe flame beveling and cutting machine offers a beveling speed of ≤3Min /pipe bevel (DN200 SCH40)/≤5Min/two-pipe bevels (DN200 SCH40).

It offers bevel cutting: Cutting off and with one bevel of the pipe at simultaneously for/cutting off and with two levels of the pipe simultaneously.

It offers good bevel quality.

Pipe Diameter Applicable: DN400/ DN600/DN800 /DN1200

Applicable Wall Thickness: 5~50 mm

Applicable Materials: Carbon steel, alloy steel, and cryogenic steel

Cutting Length: 6350MM

Bevel Shape: V

Cutting Direction: Lengthwise

Roller Bench:

(1). Structure: Three line steel roller with a fixed distance

(2). Roller Bench Length: 7000MM

(3). Driving System: Servo motor + precision reducer

(4). Rev: 0~2.5M/Min (VF step-less speed adjustment)

(5). Roller Bench Material: 45#, Surface bluing treatment

(6). Rotation Accuracy: <2.0MM

Trolley System:

(1). Trolley Travel: 6350MM (moving lengthwise)

(2). Cutting Torch Travel: 700MM (up/down); 300MM (in/out)

(3). Cutting With: Flame cutting (can be equipped with plasma cutting)

(4). Cutting Torch Angle: ±45° (adjustable)

(5). Cutting Torch Quantity: One piece of flame cutting torch/three pieces of flame cutting torch

(6). Angle Error: <2°

(7). Length Fixing Accuracy: <2.0MM

Control System: SH-2000H Flame CNC Cutting System

Length-Measuring System: CNC length measuring which is included in the control system

Conveying System: Built-in conveying system equipped with a lifter; additionally, a set of conveying systems can be provided for bevel cutting machine if necessary, and conveying can be implemented manually or electrically.

Pipe cutting industry

After-Sale Service Guideline: ” Worry what users worry, think what users think ”

Within/beyond the warranty period, when the equipment gets out of order or is damaged, the company will provide technical consulting services without or with a charge. For customer advisory, the company will supply responses on the phone within 4 hours and written replies within 8 hours. If the customer requires, within 24 hours (within the distance of 800 KM) or within 48 hours (above 800 KM), the company will dispatch experienced engineering technical personnel to the customer site to analyze and guide maintenance. They will not leave until the fault is cleaned and the customer is satisfied.