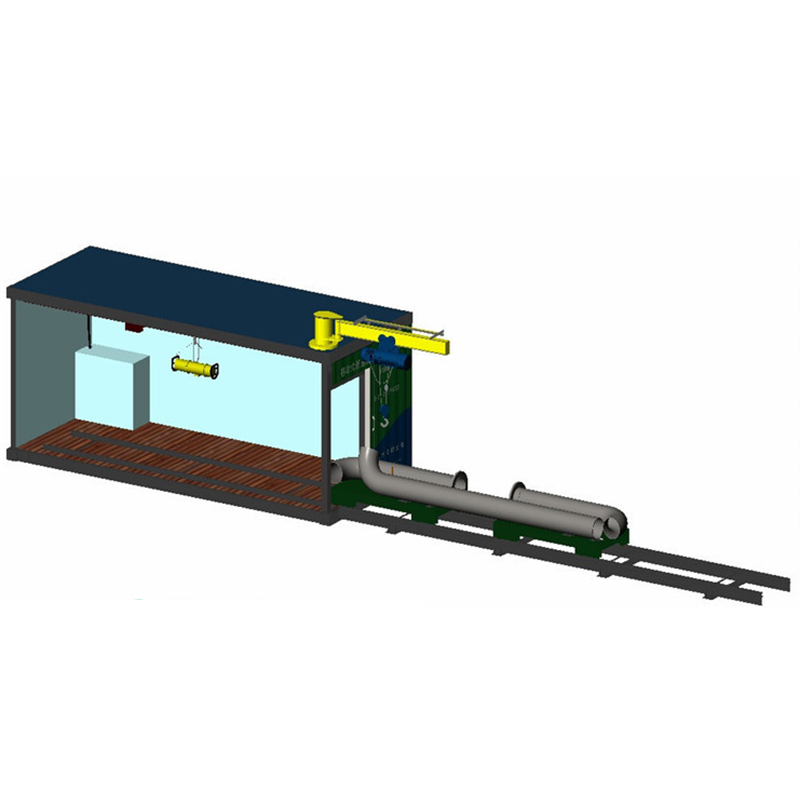

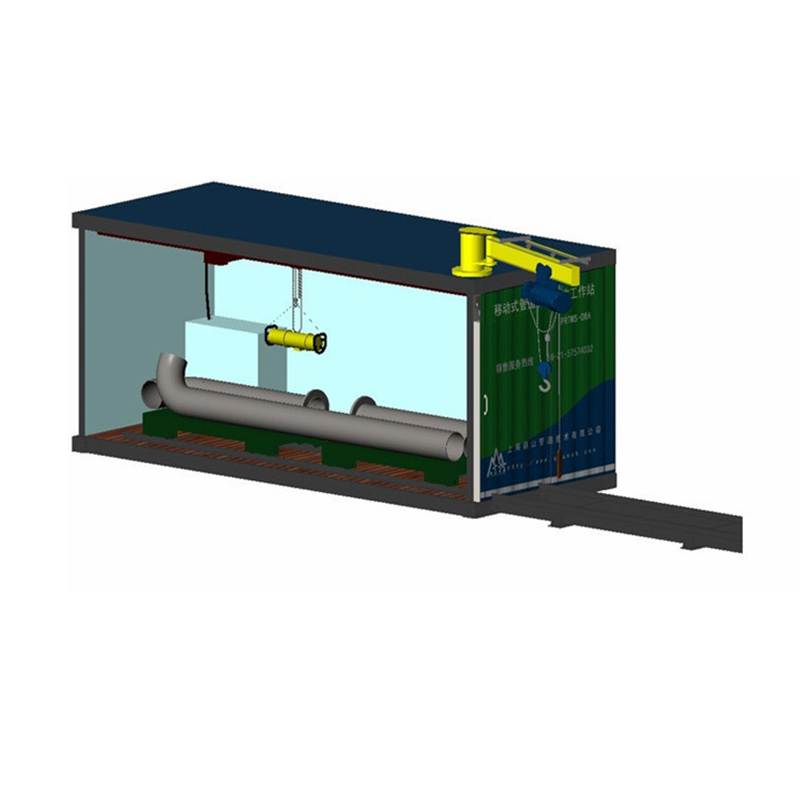

The piping radiographic test work station is a combination of one 6m container made using special techniques, one free frame light-rail crane, one pipe cantilever crane, and one split type air conditioner.

Its production efficiency is high. Utilizing a container as the carrier, it has no limitation on working radius and offers superior mobility.

One specially retrofitted 6M container; one free framework light rail crane; one pipe cantilever crane; one split-type air conditioner, one rail & trolley conveying system; lead plates installed all around (the roof: 10mm; the bottom: 16mm; others: 23mm); flaw detector power: 300KV/5MA; nondestructive testing can be done during the day to solve the bottleneck of flaw detection.

Pipe diameter applicable: DN400/DN600

Detecting power: 300KV. 5MA

Defectoscopy direction: bottom and sides

Exposure Time: 8 hours/ day, 6 days/ week

Lead Board Thickness: 10mm (top), 16mm (bottom), 23mm (others)

Limited lifting weight: 1 ton (external), 50kg (internal)

Conveying system: two trolleys are provided at the side of material feeding and discharging ends; raising and lowering pipe with the cantilever crane

Air conditioning system: 2.5 HP split air conditioner

With very good flaw detection performance, the piping radiographic test workstation is commonly used in pipe fabrication factories or yards for pipe and tube defective detection.

After-Sale Service Guideline: ” Worry what users worry, think what users think ”

Within/beyond the warranty period, when the equipment gets out of order or is damaged, the company will provide technical consulting services without or with a charge. For customer advisory, the company will supply responses on the phone within 4 hours and written replies within 8 hours. If the customer requires, within 24 hours (within the distance of 800 KM) or within 48 hours (above 800 KM), the company will dispatch experienced engineering technical personnel to the customer site to analyze and guide maintenance. They will not leave until the fault is cleaned and the customer is satisfied.